Was ist Reinstwasser ASTM Typ 1?

Veröffentlichungszeit: 10.07.2025

Die internationale Normungsorganisation ASTM hat die Spezifikation D1193 eingeführt, die einen weltweit anerkannten Maßstab für die Klassifizierung von Reinstwasser darstellt. Darunter sind ASTM Typ 1 Reinstwasser steht für den höchsten Reinheitsgrad. Es ist der Inbegriff von Wasserreinheit und ein unverzichtbarer Grundstoff in zahlreichen Hightech-Bereichen. Wie wird dieses nahezu „absolut reine“ Wasser erzeugt und welche Schlüsseltechnologien unterstützen seine Produktion? Hefei YouShui Electromechanical Equipment Co., Ltd., ein führender Anbieter von Reinstwasserlösungen, enthüllt die Geheimnisse dieses präzisen Aufbereitungsprozesses.

Definition und Anwendungswert von ASTM Typ 1

Der ASTM D1193-Standard unterteilt Laborwasser in vier Klassen (I bis IV), wobei Reinstwasser vom Typ I (d. h. Typ 1) die strengsten Anforderungen stellt:

- Spezifischer Widerstand: ≥ 18,0 MΩ·cm (25 °C)

- Gesamter organischer Kohlenstoff (TOC): ≤ 50 ppb (µg/l), wobei für anspruchsvollere Anwendungen oft noch niedrigere Werte erforderlich sind.

- Partikel: Extrem niedrig (normalerweise mit Endfiltern mit einer Porengröße von 0,2 μm oder kleiner gefiltert).

- Mikroorganismen: Extrem niedrig (normalerweise mit UV-Sterilisation und Endfiltration behandelt).

Diese extremen Reinheitseigenschaften machen es unverzichtbar in:

- Medizin/Biowissenschaften: Zellkultur, Gensequenzierung, Massenspektrometrie, High-End-Reagenzienvorbereitung, Endreinigung von Endoskopen/Versorgungsräumen und Verdünnung von Dialysekonzentrat; jegliche Verunreinigungen könnten die Ergebnisse beeinträchtigen oder biologische Reaktionen hervorrufen.

- Integrierte Schaltkreise/Mikroelektronik: Reinigung von Silizium-Wafern, Fotolithografieprozesse, bei denen Spuren von Ionen oder Partikeln zu Chipdefekten führen können.

- High-End-Labore/Inspektion und Prüfung: Als mobile Phase oder Probenvorbereitung für präzise Instrumente wie Hochleistungsflüssigkeitschromatographie (HPLC), Ionenchromatographie (IC) und induktiv gekoppelte Plasma-Massenspektrometrie (ICP-MS).

Kernvorbereitungsprozess von ASTM Typ 1 Wasser

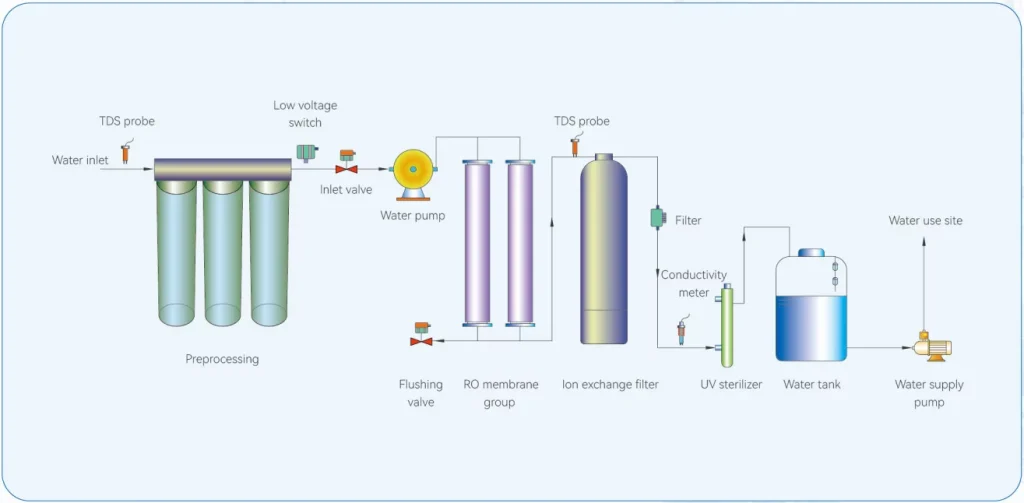

Hefei YouShui Elektromechanik Reinstwasserausrüstung verwendet eine Reihe hochentwickelter, miteinander verbundener Reinigungsmodule, um nach und nach alle Verunreinigungen aus dem Wasser zu entfernen und so letztendlich den Wasserstandard Typ 1 zu erfüllen:

Tiefenvorbehandlung: Ein solides Fundament legen

- Mehrstufige Filtration: Präzisionsfilterkartuschen fangen Partikel wie Sedimente, Rost, Kolloide und große organische Moleküle schrittweise ab.

- Aktivkohleadsorption: Entfernt effizient Chlorrückstände, organische Verbindungen, Gerüche und Farbstoffe, um empfindliche Membrankomponenten in späteren Phasen zu schützen.

- Enthärtung und Entfernung von Kalkablagerungen: Ionenaustauscherharze entfernen Kalzium- und Magnesiumionen, um Kalkablagerungen und Verstopfungen der Umkehrosmosemembranen zu verhindern.

Kernentsalzung: Duale Umkehrosmose

Durch Hochdruck wird Rohwasser durch Umkehrosmosemembranen mit nanometergroßen Poren gepresst. Über 991 TP3T gelöste Salze, Ionen, organische Verbindungen, Mikroorganismen und Wärmeenergie werden effizient entfernt. Das zweistufige RO-Design verbessert die Entsalzungsrate und die Stabilität der Wasserproduktion deutlich und gewährleistet so eine hochreine Wasserproduktion.

Tiefenreinigung: Kontinuierliche Elektrodeionisation (EDI)

RO-Wasser gelangt in das EDI-Modul. Diese Technologie kombiniert auf intelligente Weise Ionenaustauscherharze und selektive Ionenmembranen unter einem Gleichstromfeld, um:

- Ionen wandern kontinuierlich durch die Ionenmembran und werden aus dem System ausgestoßen.

- Die Harze werden durch elektrolytisch erzeugte H⁺- und OH⁻-Ionen chemisch regeneriert, ohne den Einsatz chemischer Mittel. Das Endprodukt erreicht einen spezifischen Widerstand von 15–18 MΩ·cm und bildet damit die Grundlage für weitere Verfeinerungen.

Endpolitur: Ultrareine Poliersäule

Das durch EDI erzeugte Wasser gelangt in die letzte Aufbereitungseinheit – die hochreine Poliersäule (üblicherweise ein Mischbett-Ionenaustauscherharz MB). Restliche Spurenionen werden von den Harzen tief adsorbiert, wodurch die Wasserqualität auf den theoretischen Grenzwiderstand von ≥18 MΩ·cm angehoben wird.

Kennzahlenkontrolle und -sicherung

TOC-Abbau: UV-Lampen zersetzen Reste organischer Moleküle im Wasser. In Verbindung mit anschließenden Reinstklärsäulen wird so die Einhaltung des TOC-Standards sichergestellt.

Mikrobielle Kontrolle: Durch die UV-Sterilisation wird die mikrobielle DNA geschädigt und durch die Endfiltration werden Bakterien und Partikel herausgefiltert.

Online-Überwachung und -Zirkulation: Echtzeitüberwachung wichtiger Parameter wie Widerstand, TOC, Temperatur usw. Wasser fließt kontinuierlich durch das geschlossene Polierzirkulationssystem, um eine Sekundärkontamination und eine Verschlechterung der Wasserqualität durch Stagnation zu verhindern.

Technische Zusicherung durch Hefei YouShui: Stabile und zuverlässige Quelle für Wasser der Klasse 1

Aufgrund der hohen Schwierigkeit der Vorbereitung von ASTM Typ 1 Wasser und der strengen Anforderungen seiner Anwendungen, Hefei YouShui Electromechanical's Reinstwassersystem integriert mehrere Sicherheitsvorkehrungen:

- Modulares, intelligentes Design: Die Reinigungseinheiten werden flexibel konfiguriert und entsprechend den Anforderungen an die Wasserqualität optimiert. Das System wird intelligent gesteuert und gewährleistet einen stabilen und zuverlässigen Betrieb.

- Sicherung wichtiger Materialien: Es werden hochwertige Umkehrosmosemembranen, leistungsstarke EDI-Module, Ionenaustauscherharze mit geringer Auslaugung und hochtransparente Quarz-UV-Lampen verwendet.

- Online-Überwachung und Frühwarnung: Echtzeitanzeige der wichtigsten Wasserqualitätsparameter (Widerstand, TOC, Temperatur, Durchflussrate usw.) mit Warnmeldungen bei Abweichungen, um sicherzustellen, dass die Wasserqualität immer kontrollierbar ist.

- Professioneller Service-Support: Umfassende Services vom Lösungsdesign über die Installationsfehlerbehebung bis hin zum Austausch von Verbrauchsmaterialien und zur Wartung gewährleisten einen langfristig hocheffizienten Betrieb des Systems.

Hefei YouShui Electromechanical Equipment Co., Ltd. bietet mit seinem umfassenden Verständnis des Prozesses und seiner kontinuierlichen technologischen Innovation eine kontinuierliche Versorgung mit „reinem Strom“, der den strengsten Standards für medizinische Einrichtungen, High-End-Labore, die Industrie für integrierte Schaltkreise sowie Inspektions- und Testinstitute entspricht und so die Reinheit der wissenschaftlichen Forschung und die Grundlage der industriellen Entwicklung schützt.

.jpg)